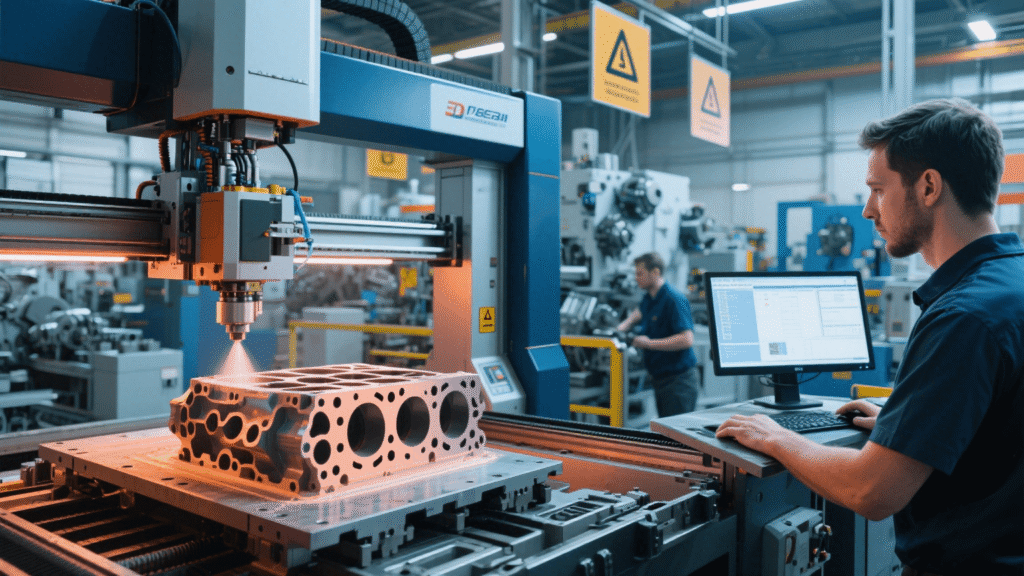

The construction industry is a major contributor to environmental pollution and resource depletion. 3D printing technology offers a more sustainable alternative. One of the key advantages of 3D printing in construction is the reduction of material waste. Traditional construction methods often involve cutting and shaping materials on – site, resulting in a significant amount of waste. With 3D printing, materials are used more efficiently, as the printer can precisely deposit the required amount of material to create the desired structure.

In addition, 3D printing allows for the use of new and sustainable building materials. For example, some 3D – printed buildings are made from recycled materials, such as plastic waste or construction debris. This not only reduces the demand for virgin materials but also helps to divert waste from landfills. Moreover, 3D – printed buildings can be designed with better insulation properties, reducing energy consumption for heating and cooling.

The speed of construction is also greatly improved with 3D printing. Large – scale 3D printers can construct walls and other structural elements in a fraction of the time it would take using traditional methods. This can lead to shorter project timelines and lower labor costs. However, there are still challenges to address, such as the need for regulatory approvals for 3D – printed buildings and the development of standardized construction practices.