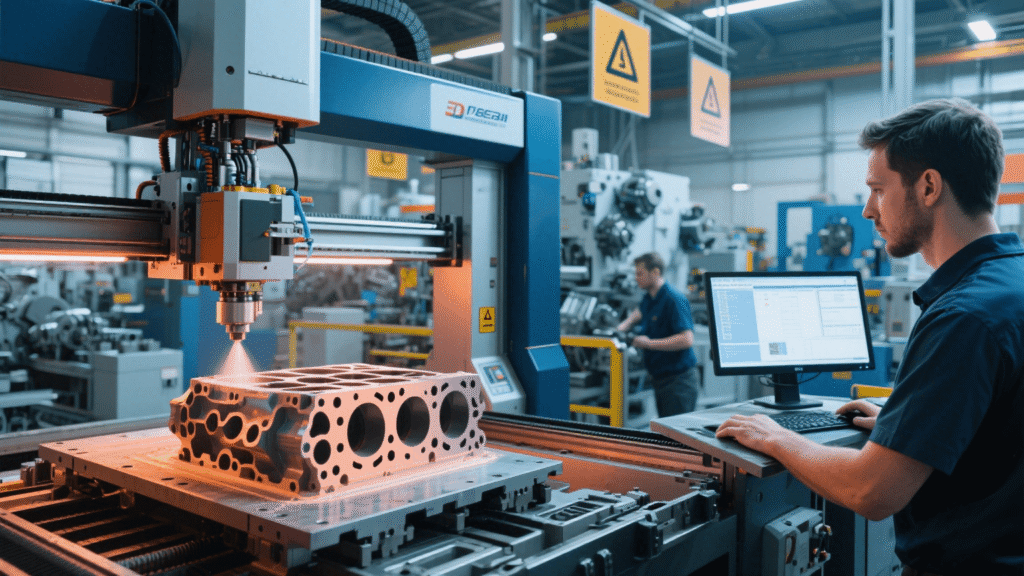

In the traditional manufacturing landscape, long – established processes often involve multiple steps, substantial material waste, and lengthy lead times. 3D printing technology is now disrupting this status quo. It allows for the direct creation of objects from digital models, bypassing many of the intermediate steps in conventional manufacturing. For example, in the production of complex mechanical parts, traditional methods may require the assembly of multiple components. With 3D printing, these parts can be printed as a single, integrated piece, reducing the risk of assembly errors and improving overall product quality.

Moreover, 3D printing enables on – demand production. Manufacturers no longer need to maintain large inventories of finished goods. Instead, they can produce parts as they are needed, which is particularly beneficial for industries with fluctuating demand. This flexibility also allows for rapid prototyping. Designers can quickly create and test multiple iterations of a product, accelerating the innovation cycle. As the technology continues to advance, we can expect to see more small – and medium – sized enterprises adopting 3D printing to gain a competitive edge in the market.

The supply chain is another area that is being transformed by 3D printing. Instead of relying on a global network of suppliers for various components, companies can potentially produce many of these parts in – house using 3D printing. This not only reduces the risk of supply chain disruptions but also gives companies more control over the production process. However, there are also challenges to overcome, such as the need for standardized materials and processes, as well as the development of skilled personnel to operate and maintain 3D printing equipment.