CDR PEGASUS

Revolutionary 3D Printing Solutions | Hong Kong.

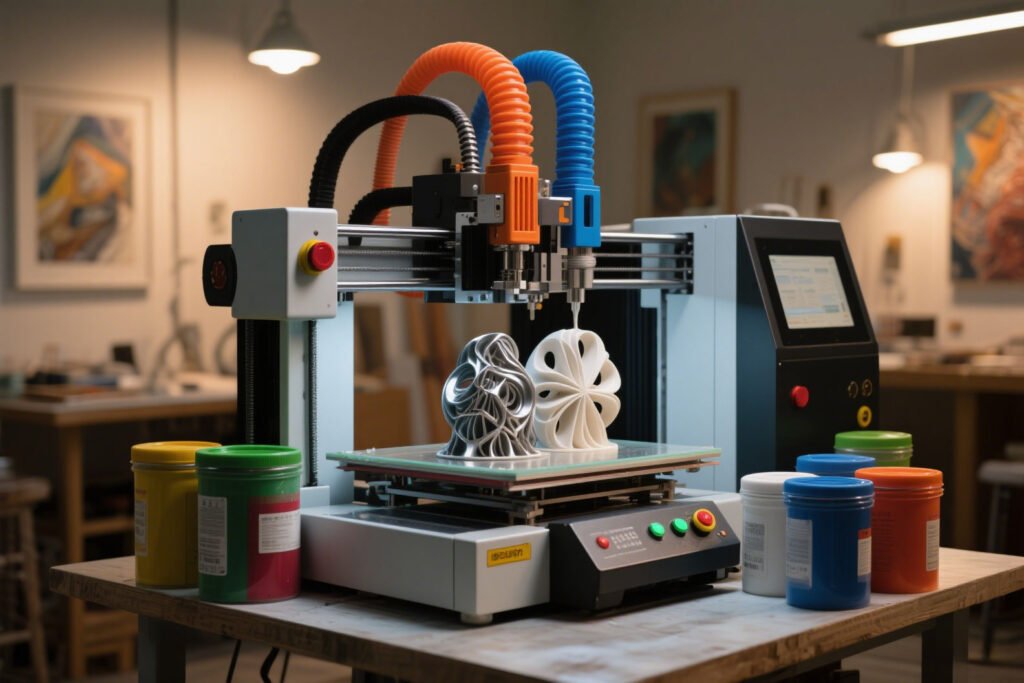

Unlimited Manufacturing Possibilities

From concept to reality, we transform your ideas into precision-engineered products using cutting-edge 3D printing technology.

Our Competitive Advantages

Industrial-Grade Equipment

Our facility houses premium 3D printing systems including Stratasys Fortus 450mc, EOS M400-4, HP Multi Jet Fusion 5200, and Formlabs Form 3L printers, ensuring exceptional quality and precision for every project.

Comprehensive Material Portfolio

We work with an extensive range of materials including ABS, PLA, PETG, Nylon, Carbon Fiber composites, Titanium, Stainless Steel, Aluminum alloys, and specialized engineering plastics to meet your exact specifications.

Expert Design Integration

Our team is proficient in all major 3D design software including SolidWorks, Fusion 360, Inventor, Rhino, Blender, and KeyShot, ensuring seamless workflow from design to production.

Rapid Prototyping Excellence

From initial concept validation to functional prototypes, we deliver industry-leading turnaround times without compromising on quality or precision engineering standards.

Scalable Production Solutions

Whether you need a single prototype or high-volume production runs, our flexible manufacturing ecosystem adapts to your requirements with consistent quality control.

Global Logistics Network

Based in Hong Kong’s strategic location, we provide worldwide shipping solutions with secure packaging and tracking for international clients across all continents.

Key Capabilities

Precision Engineering

Ultra-high resolution printing with tolerances down to ±0.1mm, suitable for aerospace, medical, and automotive applications requiring exact dimensional accuracy.

Multi-Material Processing

Advanced capability to print with multiple materials simultaneously, enabling complex assemblies and functional prototypes with varying material properties.

Post-Processing Excellence

Complete finishing services including support removal, surface smoothing, painting, and assembly to deliver production-ready components.

Quality Assurance

ISO-certified quality management systems with comprehensive testing and inspection protocols ensuring consistent, reliable results for critical applications.